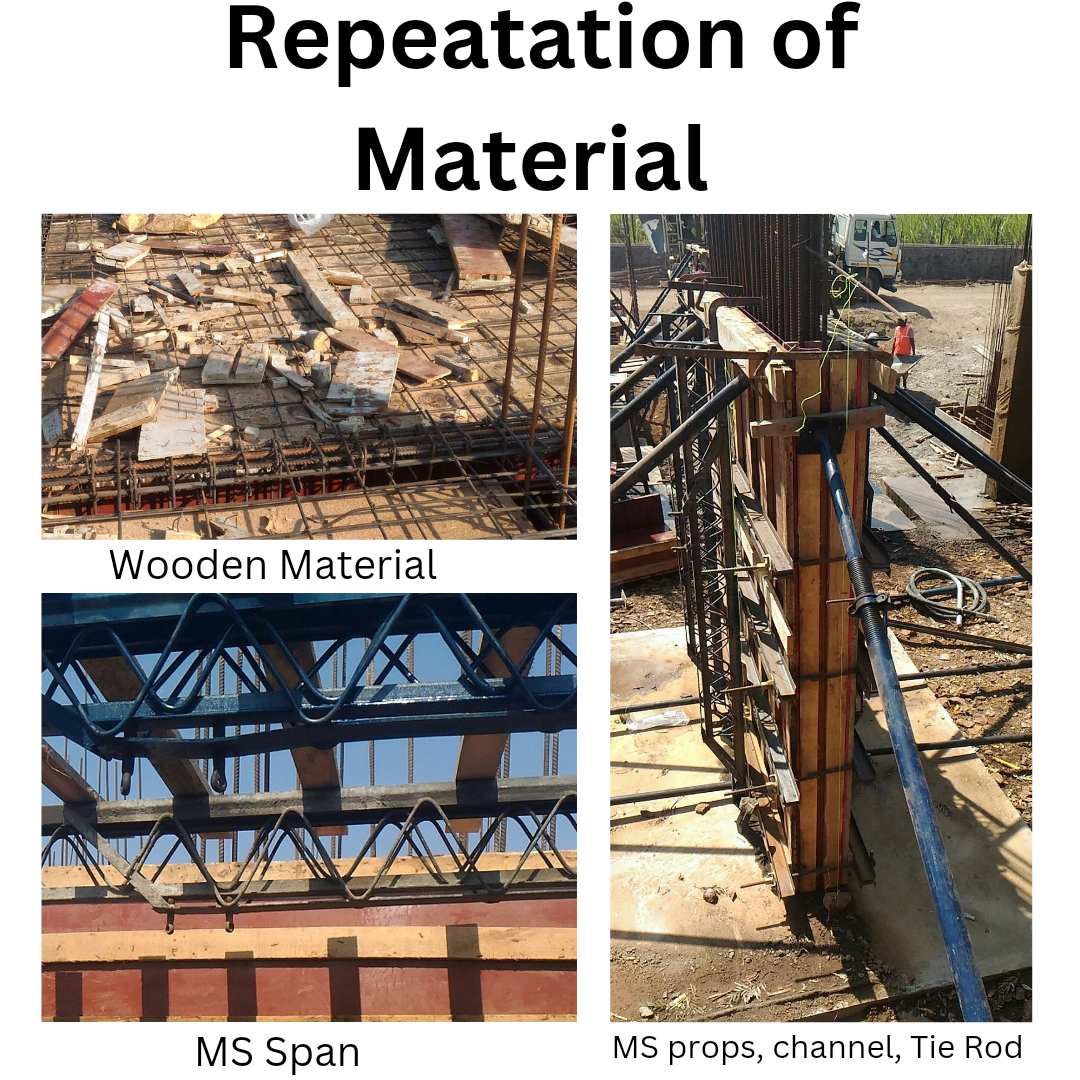

In building construction, the use of material repetitions refers to the practice of reusing specific materials or components in multiple locations or throughout different phases of construction.

This approach can offer various benefits, including cost savings, improved efficiency, and consistency in design and construction.

However, it is essential to follow certain standard rules and considerations to ensure the effective and safe implementation of material repetitions.

Material Compatibility:

Before using material repetitions, it is crucial to consider the compatibility of the materials with the specific construction elements and conditions. Materials should be chosen based on their suitability for the intended purpose and their ability to withstand environmental factors such as moisture, temperature variations, and structural loads.

Structural Integrity:

Material repetitions should not compromise the structural integrity and safety of the building. Each component must be designed and installed according to the applicable codes and standards, considering the specific loads and forces acting on them. Structural analysis and calculations should be performed to ensure that repeated elements can adequately support the required loads.

Quality Control:

Maintaining consistent quality across repeated elements is essential. Quality control measures should be implemented to ensure that the materials used meet the required specifications and standards. Regular inspections, testing, and documentation should be conducted to verify the quality of the repeated elements and identify any defects or deviations.

Construction Tolerances:

Construction tolerances play a crucial role in material repetitions. It is important to establish appropriate tolerances for the repeated elements to ensure proper alignment, fit, and functionality. Strict adherence to tolerances during fabrication and installation is necessary to avoid issues such as gaps, misalignments, or compromised performance.

Installation Guidelines:

Clear installation guidelines and procedures should be established for the repeated elements. These guidelines should specify the correct methods, techniques, and tools to be used during installation. Proper training and supervision of construction personnel involved in the installation process are crucial to ensure consistent and accurate implementation of material repetitions.

Maintenance and Durability:

Considerations should be given to the maintenance requirements and durability of the repeated elements. Adequate access for maintenance, such as cleaning, inspection, and repairs, should be incorporated into the design. Additionally, materials should be chosen based on their durability, resistance to deterioration, and expected lifespan to minimize the need for frequent replacements.

Aesthetics and Visual Variations:

While material repetitions can provide visual consistency, it is essential to address any potential monotony or lack of visual interest. Design considerations should include variations in texture, color, patterns, or other visual elements to create an aesthetically pleasing and engaging environment.

Flexibility and Adaptability:

Material repetitions should allow for flexibility and adaptability in case of future modifications or renovations. Considerations should be made for easy replacement or removal of repeated elements without causing significant disruptions or compromising the overall structure.

Cost and Value Engineering:

Material repetitions can offer cost savings through economies of scale, reduced material procurement, and simplified construction processes. Value engineering techniques should be employed to optimize the design and construction, ensuring that material repetitions contribute to cost efficiency without compromising quality or functionality.

Documentation and Communication:

Accurate and detailed documentation is vital when implementing material repetitions. This includes specifications, drawings, installation guidelines, quality control records, and any modifications or variations.

Effective communication between the design team, contractors, and suppliers is essential to ensure that everyone understands and follows the standards and guidelines associated with material repetitions.

By adhering to these standard rules and considerations, the use of material repetitions in building construction can lead to improved efficiency, cost savings, and visual consistency. However, it is important to carefully evaluate each project's specific requirements and consult with relevant professionals, including architects, engineers, and contractors, to ensure that the implementation of material repetitions is suitable and effective for the particular construction project.

0 Comments